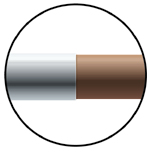

Mono Strand

The Lead wire of a monostrand pintle pin is ideal for facilitating the task of seaming your belt fabrics. It allows you to quickly and easily seam a single strand of monofilament through your belt fabric seam.

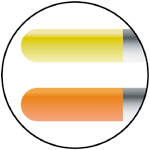

Fluorescent paint (optional yellow or orange) can be applied on the tip of the pintle pin lead wire to facilitate the installation.

Choose between standard or laser connection of leader to sleeve

Sleeve link with monofilament

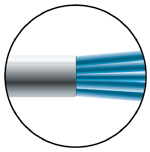

Multi Strand

The multiple strands of the multistrand pintle pin help fill the entire space in the loops of your belt fabric seam, decreasing the total free space left in the seam. This lowers the wear and increases the life of the seam.

Fluorescent paint (optional yellow or orange) can be applied on the tip of the pintle pin lead wire to facilitate the installation

Choose between standard or laser connection of leader to sleeve

Sleeve link with monofilament

Split

When you need a smaller connection sleeve diameter without

decreasing the number of strands you want in your seam the split pintle pin is

perfect for you. Its design allows you to keep the same diameter and number of

monofilament strands while reducing the connection sleeve size. The setup

of this pintle pin has the leader

linked, by the main sleeve, to one or several monofilaments and another metal

wire. The second metal wire is then linked to additional monofilaments by a

second sleeve.

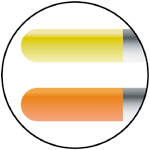

Fluorescent paint (optional yellow or orange) can be applied on the tip of the pintle pin lead wire to facilitate the installation.

Choose between standard or laser connection of leader to sleeve

Sleeve link with monofilament

Total Split

In this pintle pin design the leader and several metal wires are

linked by a main sleeve. Each metal wire, of specific length and regular

spacing, is then linked to a monofilament by another sleeve. The total

split pintle pin design gives the same added advantage as the split pintle pin

but with an even smaller overall connection sleeve diameter.

Fluorescent paint (optional yellow or orange) can be applied on the tip of the pintle pin lead wire to facilitate the installation.

Choose between standard or laser connection of leader to sleeve

Sleeve link with monofilament

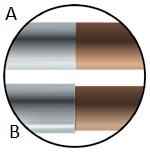

Reduced

This Lippert patented technique allows a single strand

pintle pin to have a connection sleeve size very close to the diameter of the

monofilament. In turn this creates less friction and easier insertion for

tight seams or to use a larger overall monofilament diameter for the seam.

Fluorescent paint (optional yellow or orange) can be applied on the tip of the pintle pin lead wire to facilitate the installation.

Choose between standard or laser connection of leader to sleeve

Sleeve link with monofilament comparison

A =

Reduced connection

B =

Regular connection

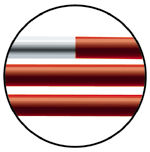

Rectangular Connection

Straight pintle pin where the leader and the flat monofilament are linked by a rectangular sleeve.

For those more rectangular seams or flat monofilament applications a rectangular connection on the flat monofilament is best. This type of connection on a flat monofilament will be smoother than a round one.

Fluorescent paint (optional yellow or orange) can be applied on the tip of the pintle pin lead wire to facilitate the installation.

Choose between standard or laser connection of leader to sleeve

Sleeve link with monofilament

Tail

A tail wire at the end of your pintle pin allows you to lock the end of the pintle pin to your belt fabric. The tail wire can be manufactured in any specific length and with or without the flourescent marker on the end.

Fluorescent paint (optional yellow or orange) can be applied on the tip of the pintle pin lead wire to facilitate the installation.

Choose between standard or laser connection of leader to sleeve

Sleeve link with monofilament

Needle

Wire needles allow you to insert any monofilament through the loop in the end of the needle and seam this monofilament in your belt fabric. It is custom made and thus available in many different diameters and loop sizes.

Fluorescent paint (optional yellow or orange) can be applied on the tip of the pintle pin lead wire to facilitate the installation.

Choose between standard or laser connection of leader to sleeve

Sleeve link with loop.