Basic Packaging

Rolling

We neatly roll our pintle wires in either an 8" or 10" diameter. The 8" coil is more compact and easier to pack with the fabric, felt or conveyor belt. The 10" coil is a bit larger and allows the lead wire to take less memory of the curved coil. Our pintle wires are then each placed in a zip lock plastic bag for protection and storage. We can also bag them in packages such as sets, or 10 per bag

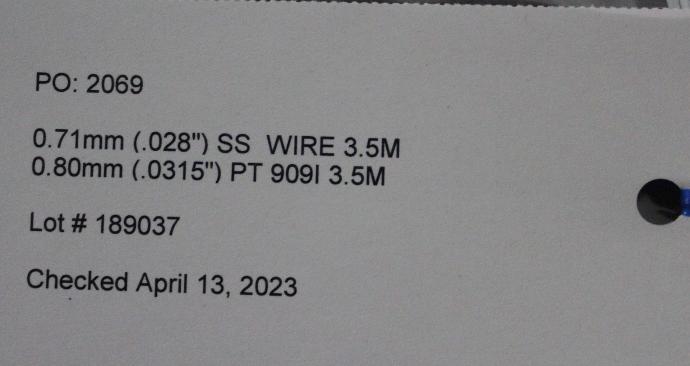

Labeling

Each one of our pintle wires are individually labeled for easy identification, quality control and tracking purposes. These labels indicate the description of the pintle wire as well as the date ordered and purchase order number. With this information we can track the entire production process of each pintle wire we manufacture.

Plastic Reels

Model STP

The durable plastic shell guards against damage and kinks while also protecting the monofilaments against dust, UV lighting and other substances.

Advantages

- Made of durable plastic, protects the entire pintle pin during shipment and storage.

- Prevents multi-strand pintle pin monofilaments from tangling.

- Secure double locking system prevents pintle wire from slipping back into plastic reel.

- Complete access to pintle pin at all time.

- Simple design & Patented.

Model SCC and DCC

Our reels protect the pintles during transportation and storage. The durable plastic shell guards against damage and kinks while also protecting the monofilaments against dust, UV lighting and other substances.

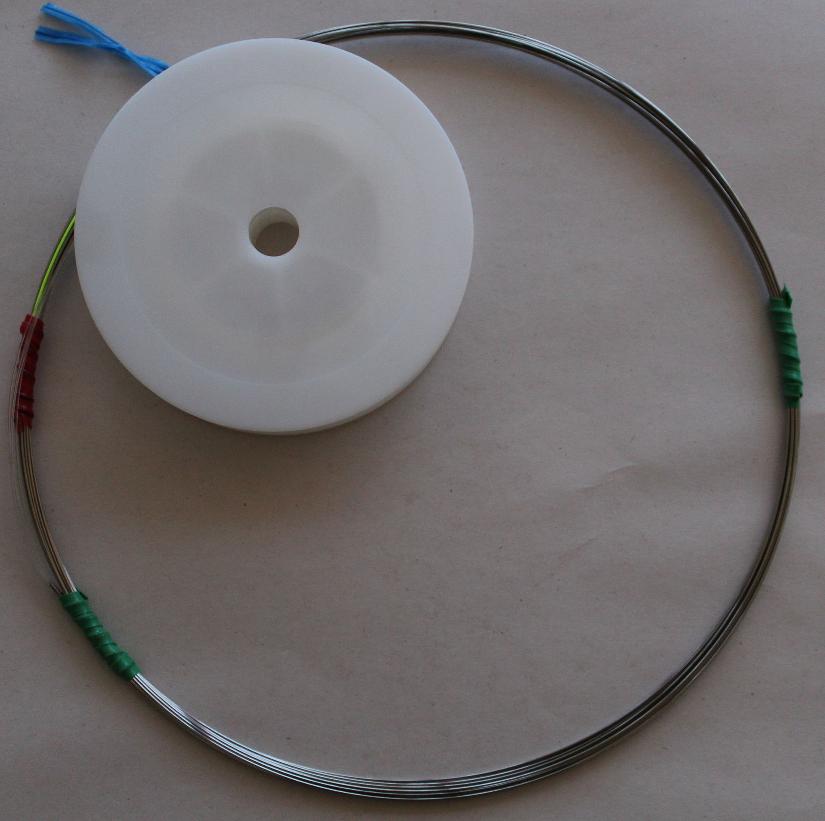

Spool

Plastic Spool Advantages

- Protects the monofilament during shipment and storage.

- Prevents multi-strand pintle pin monofilaments from tangling.

- Compact and easy to use design.

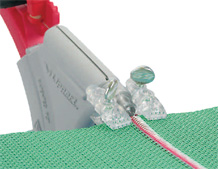

Insertion Device

Our newest reel model allows for an insertion device attachment that will seam the pintle into the belt, felt or fabric. The attachment clamps on to the seam edge and the user can then continuously advance the pintle wire into the seam by squeezing the trigger of the device repeatedly. This is done until the wire exits the other side of the seam. The wire can then be pulled to seam the monofilament of the pintle into the seam. A small amount of lubricant can also be added to the dispenser after the wire has been seamed so as to lubricate only the monofilament portion of the pintle before it is pulled into the seam.

You will appreciate the multiple advantages and characteristics of the insertion device.

- Easy to use.

- Avoids damage to the pintlepin.

- Increases the speed of pintlepin installation.

- Automatic lubricating system.

- Pivoting head.

- Adapts to our plastic reel.

- Ergonomic design.

- Solid and efficient conception.

- Attaching system to the felt / conveyor.

- Light, compact and strong.